Goal of CARE

Crash absorbers are an important safety feature during road works. Strict compliance with the rules and extra caution on the part of road users are intended to significantly increase road safety during road works. At present, crash absorbers are always operated by a driver. This regularly raises questions about safety and efficiency in the workplace, particularly with regard to the safety of the crash absorber driver. Realising that up to a third of labour costs are spent on insurance and that collisions occur on average once a week, the search for greater safety, efficiency, information and automation is essential.

The partners in CARE – Movias, Fero Groep, Orange and V-tron – want to jointly realise a 5G use case with remote-controlled crash absorbers. 5G wireless networks meet the high demands placed on the use case of tele-operated vehicles.

The use of tele-operated crash barriers during road works will increase the safety and efficiency of these activities. Fewer road workers will be present in hazardous areas, and the crash barriers can be moved more quickly and efficiently.

After all, automated vehicles, made possible by smart 5G networks, will be a major game changer for the near and distant future.

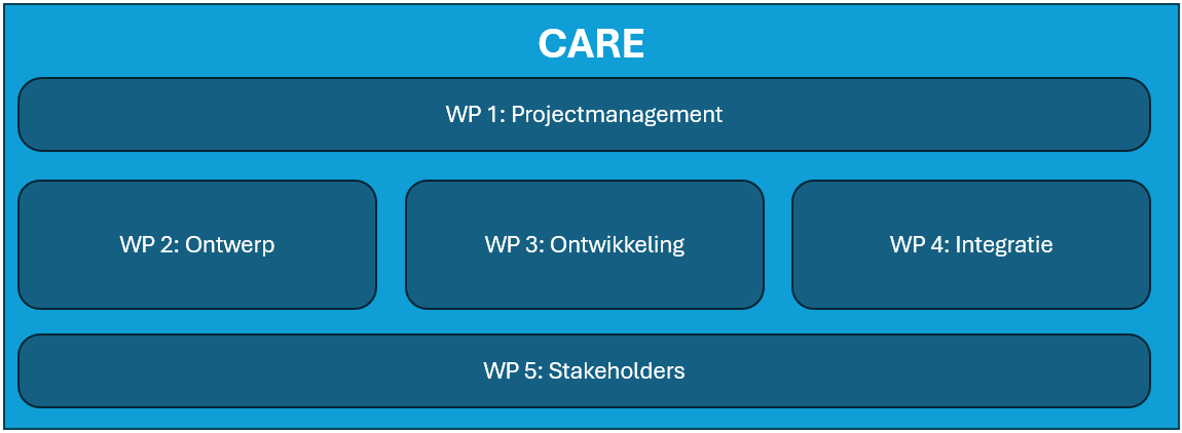

Project approach

The various tasks have a lead time as indicated in the planning schedule under expected results.

- WP1 – Project Management

- 1.1 Coordination: a steering group with participants from all project partners is organised every two months.

- 1.2 Administration: this sub-package covers reporting and project administration.

- WP2, WP3 and WP4 are coordinated and organised around two major milestones: the internal test in November 2025 (M1) and the Demo in May 2026 (M2).

- WP2 (Design) and WP3 (Development) are working together towards the first integration in WP4 for M1 in November 2025. This will be followed by further evaluation and optimisation (sub-task 4.2). This will result in further development of the various components (WP3) with integration (sub-task 4.3) leading to the final demonstration (sub-task 4.4). Finally, monitoring and a final evaluation are planned.

- WP5 (Stakeholders) involves external stakeholders in the process. Relevant stakeholders are brought together on the basis of sub-task 5.1. Three consultations are planned with various actors, who will also be involved in the demonstration. Communication with both the professional sector and the “outside world” will be handled by sub-task 5.2. Finally, the roadmap will be developed in sub-task 5.3, which will include both the lessons learned and the next steps.

Contact V-tron:

Expected results:

The project will run from 1 January 2025 to 30 June 2026. A duration of 18 months.

The project is being carried out in Belgium. The project labs and offices of the participating partners are being used for this purpose.

In November 2025, an initial internal test (M1) will be organised on the premises of Fero Group in Willebroek with one tele-operated bot absorber.

A demonstration (M2) is planned for May 2026 on an unused section of the E19 motorway in Machelen. Three tele-operated crash absorbers will be controlled from a tele-operated control centre in the Fero Group offices in Willebroek.

V-tron is going to convert a truck to tele-operation without making any modifications to the CAN bus. This is an interesting challenge, but it can certainly be done with the right approach and components. The type approval of the truck must not be negatively affected and the truck must remain usable on public roads.

Challenges

CARE (Crash Absorber for Remote-operated Equipment) aims to develop and deploy tele-operated crash absorbers for Belgian roads. These special vehicles will be controlled via 5G networks to ensure rapid and flexible deployment wherever they are needed.

The vehicles (currently lorries) will have advanced remote control capabilities, including the ability to lower the bumper and display images on the screens.

In addition to converting the truck, V-tron is setting up a realistic working environment for the tele-operators. Within the operating environment, no attention is paid to specific inputs, such as simulating the shaking or vibration of the truck. To ensure strict operation, the necessary safety measures and access restrictions will also be considered.

Naturally, V-tron is closely involved in the roll-out of both demonstrations M1 and M2, and the necessary integrations.

Project partners:

The Crash Absorber for Remote-operated Equipment (CARE) project was made possible in part by a grant from the Flemish Federal Public Service Economy, SMEs, Self-employed and Energy.