Goal of LODYT

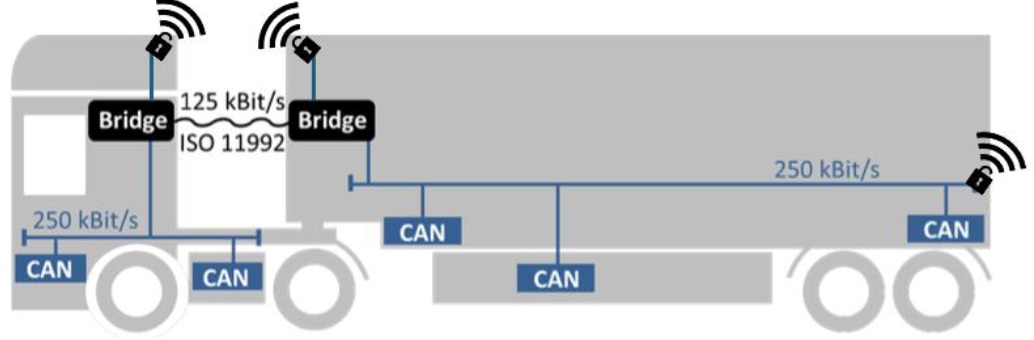

In the Local Dynamic Twin (LODYT) project, a partnership of companies and a knowledge institution is developing a completely new control unit for goods transport trailers, with a sustainable housing, a data set for communication with the tractor unit and other vehicle units in the combination, V2X communication and an interface/software for drivers and fleet management.

The aim is to develop and market a generic intelligent control unit for data exchange between trucks and trailers and to develop a dataset for communication in multi-vendor truck-trailer combinations and V2X communication with infrastructure and other road users as an extension to existing standards. This is a completely new product that can provide intelligence to trailers, which until now have been a passive part of vehicle combinations.

The targets set for emission reduction and transition to other energy carriers and safety requirements in road transport are accompanied by an increasing need for intelligence and data exchange between vehicle units and with the environment. The control unit provides this, both within the vehicle and with other vehicles, objects and infrastructure.

Project approach

The combination of V2X with all sensor information from the lorry and trailer enables yard automation, autonomous driving and other applications for logistics companies, government and road authorities.

The control unit should be seen as an enabling technology for further innovations in road transport, making it possible to drive complex combinations with multiple drive systems and steering axles distributed across the vehicle and to move them safely in traffic. At LODYT, we focus on both the technical application and the human-machine interface; the disclosure of information to the driver, the operation and provision of information to fleet management.

The consortium consists of four specialised companies and a knowledge institution that together possess the necessary expertise for the development and marketing of the V-Box:

- V-tron BV develops the intelligent controller and data protocols, tests a king-pin sensor

- TMC BV develops V2X applications and data protocols, human-machine interfaces (HMI) and apps for drivers.

- Recreate BV develops human-machine interfaces (HMI) and apps for drivers.

- Econogy BV co-development of data protocols and HMI, cabling, practical testing on (prototype) trailers with electric drive and steering system

- Saxion ThermoPlastic composites Application Center develops sustainable housing from thermoplastic composite

Contact V-tron:

Expected results:

LODYT focuses on the development of market-ready (from TRL-4 to TRL-8) products in the form of a plug-and-play control unit/ECU for trailers, with cabling, software and interface, in a durable plastic housing, enabling two-way communication between the towing vehicle, trailer and surroundings.

The datasets and software can be used in the control unit, but also on ECUs from truck OEMs.

- Development of a dataset for communication in multi-vendor truck-trailer combinations (as long as there is no EU standard, our dataset can serve as the basis for an EU standard).

- Improvement and application of the V2X dataset as used in live tests in the Netherlands and Germany by V-tron and TMC in practical trials in 2023 and 2024.

- Application in an existing ECU, for example the Contibox4 or the current generic ECU that we have already used in various projects.

- Development of the control unit, cabling and software, universal communication module for lorry-trailer combinations.

- Development of a lightweight, durable composite housing for the control unit and other ECUs.

- Development and testing of a production version of a kingpin sensor for angular rotation.

- OTA two-way communication, for real-time data collection and processing, software updates and learning network.

- Development of an HMI app for truck interfaces (visible/accessible in the truck’s dashboard and via iOS/Android applications).

- Development of a universal control unit interface to be added to the dashboard of lorries.

- Development level TRL-8 system complete and tested

Challenges

A durable housing is being developed for the ECUs to be installed in the trailer. In view of the extreme conditions during installation on the trailer (sea water, dust, dirt, vibrations, stone chips, brine), we have opted to develop a durable housing made of fibre-reinforced thermoplastic as a replacement for the usual aluminium housing.

The current housings are an overkill of material, do not exactly meet the required material properties and require the necessary post-treatment against corrosion and moisture penetration. Plastic housings give the designer more freedom of form, are easier to seal and transmit much less vibration.

The composite to be used is highly recyclable and, thanks to good design and the choice of the right matrix and fibres, with the addition of a small amount of metal particles for EMC shielding, can be tailored precisely to our application. This technology, which has not yet been used outside the aerospace industry, is promising and can also be applied to other components in trailers and lorries, including sensor housings.

The products are aimed at the towed vehicle market, which, unlike the towing vehicle market, is highly fragmented, with over 1,000 manufacturers in the EU. We want to contribute to the emerging communication standard via the supply side of towed vehicles. For the majority of the towed vehicle market, this development is a distant prospect, and they are not taking any initiative in this area. This therefore presents opportunities for a new market.

Project partners:

The Local Dynamic Town (LODYT) project was made possible in part by an ERDF East and an EU grant.